As the past CEO and co-owner of Trans Ocean Distribution (TOD) until we sold the company to the JF Hillebrand Group, I am up to date with the latest developments in the flexitank market and particulary in the areas relating to technical developments.

Very early on I was instrumental in pursuing a standard for the industry and initiated discusions with, amongst others, the Container Owners Association (COA). While there is still a long way to go to reach a set of representative tests for the flexitank and container system the PAS 1008:2014 is a good first step in that direction.

While the PAS does address material and some other testing at the component level, the only test of the system as a whole is the 2g longitudinal rail impact test. Much of the PAS and the updated CoP V4 focuses on the processes and not sufficiently on the physical testing of the system as a whole. This is a test borrowed from the rail industry to essentially test the stability of cargo under defined blocking and bracing configurations but. A similar test is also applied to tank containers but for different reasons, namely to test the tank and frame structure integrity under impact. In our opinion, this test is necessary but not sufficient and does not on its own represent the full spectrum of operating conditions and associated force systems typically present during a transport cycle. The rail test is a first step but a more comprehensive and representative suite of tests need to be designed and applied.

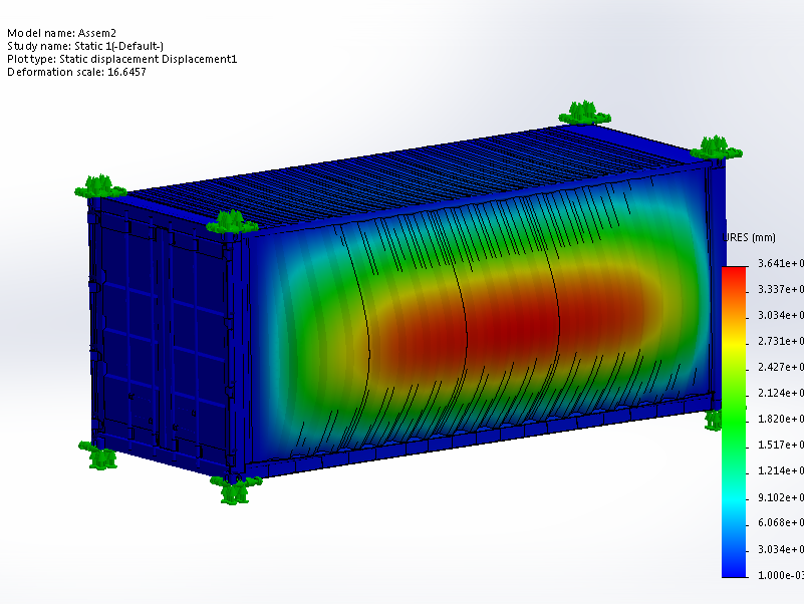

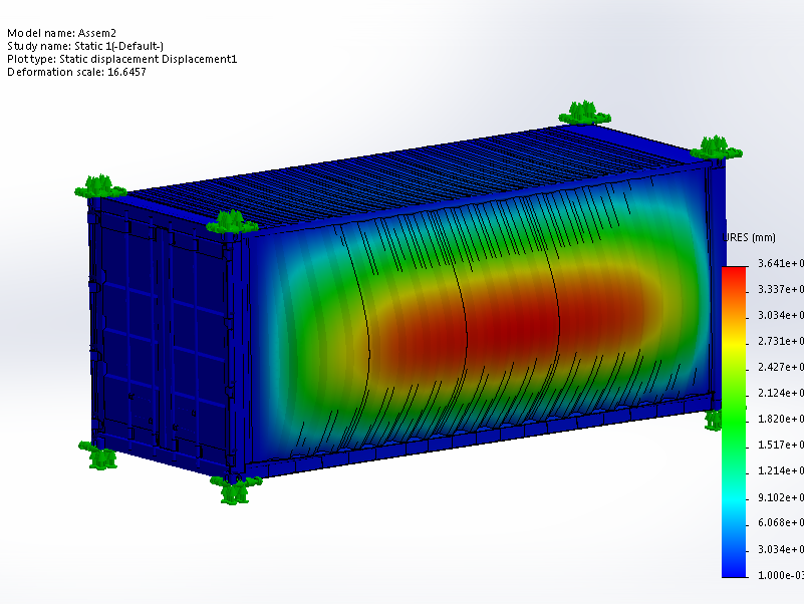

With this in mind we have developed a comprehensive Finite Element Analysis (FEA) using a detailed CAD model of the container and flexitank. The analysis covers the full range of operating conditions and it is our intention that this analysis be used as the basis

for developing further tests so that the flexitank industry can progress safely. We believe this is the most comprehensive body of work undertaken on this subject by two of the most experienced engineers in the industry and both with design and operating experience of a variety of container types and associated equipment.

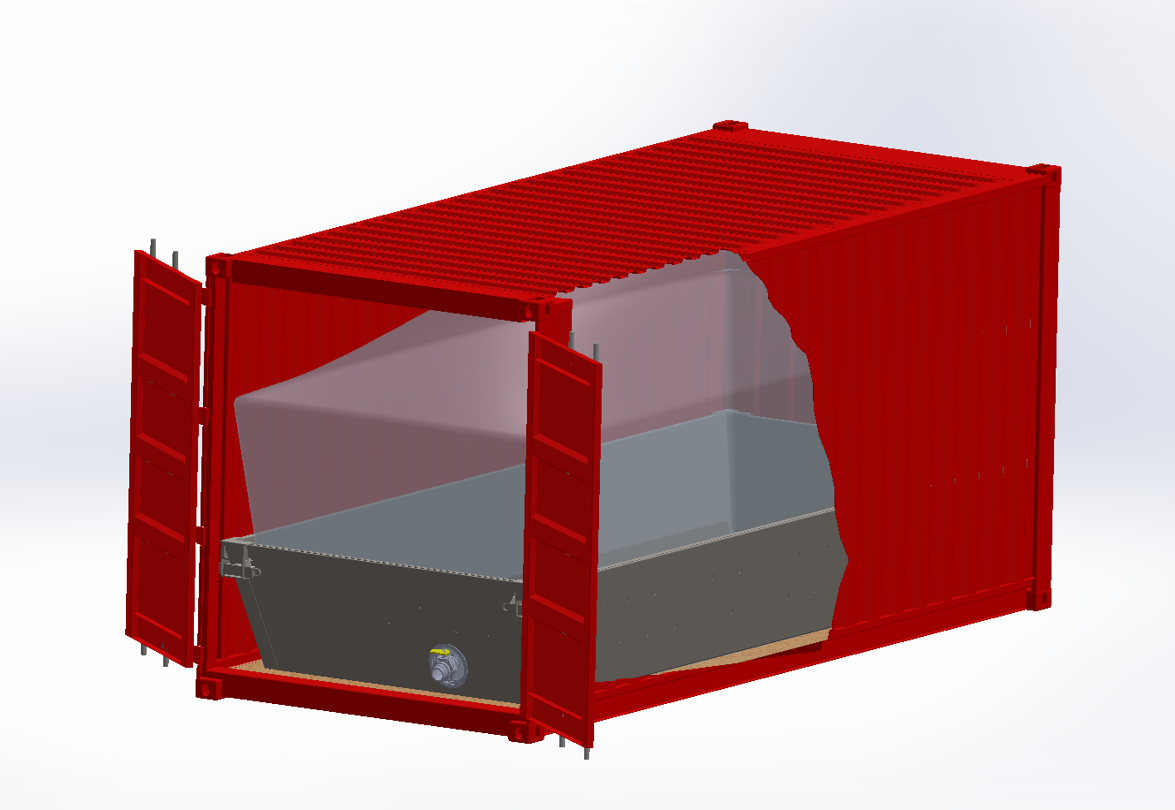

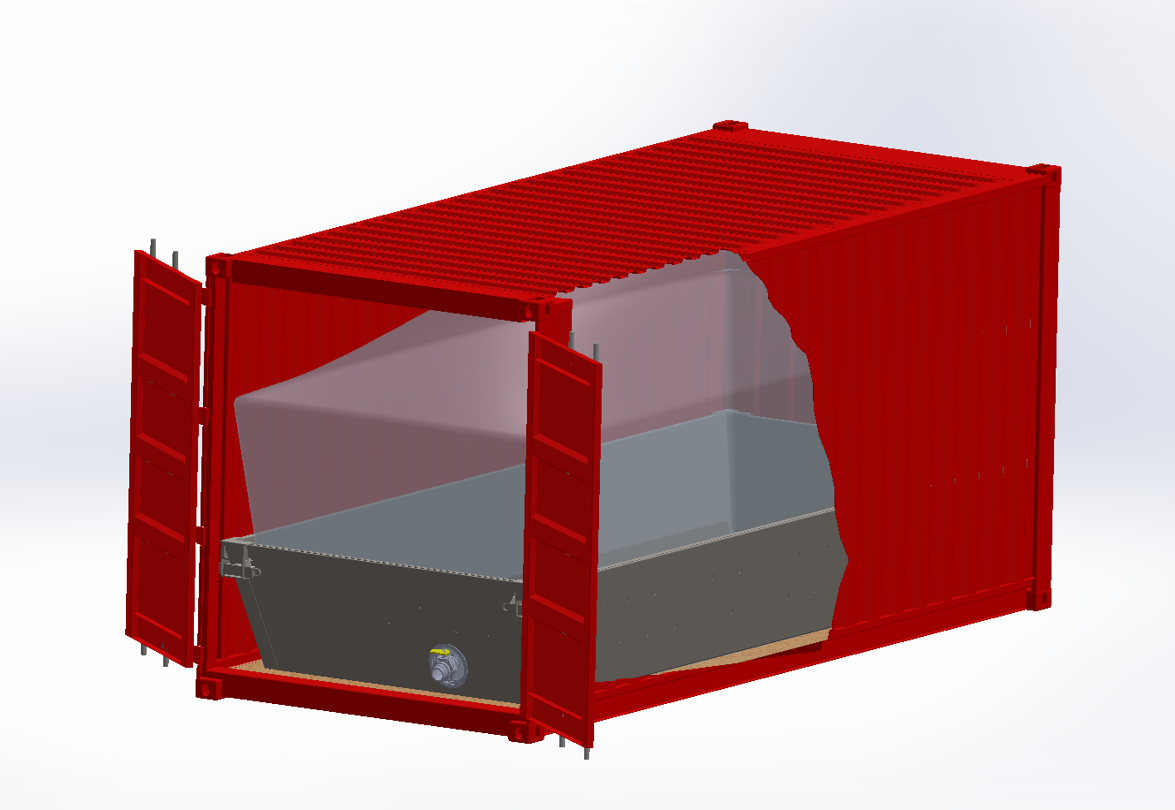

As part of the study I have teamed up with Martin Clive-Smith of Clive-Smith Associates Limited and we have formed a company called Clive-Smith Mckenna Limited based out of the UK. We have developed a patented device, the FlexiBin S3, which will safely allow up to 27 000 kg of product to be carried in a container. Please refer to the presentation below for details.

The FlexiBin S3 is not a solution in search of a problem. As the flexitank industry continues to grow so do the challenges associated with this growth. Not only do shippers want to load more product but damage to containers from flexitanks are an estimated $136 million annually. Click here to view report complied by Germanischer Lloyd relating to contaner side wall damage caused by flexitanks

We hope that the market will embrace this innovation and not view it as a threat but rather as a way to improve payload and safety while also providing better economics all round.

We believe we can act as independent professionals in working with industry participants to help develop and build on existing efforts while ensuring a testing environment that is both cost effective yet practically relevant to the future of the industry.Click on the images below to view presentations.

Demonstration of the simple and easy handling of the FlexiBin S3

To contact me about a detailed financial analysis of how this saves money please click here

As the flexitank market continues to grow so does the risk that poor handling of a container can cause severe damage to the container and cargo and also potentially to public safety. Brendan McKenna & Associates, LLC is able to provide rigorous analyses based on modeling of the flexitank and container system to provide reliable guidance as to how to best protect against such occurrences and reduce risk accordingly.

The animation below indicates the expected flexing of a container side wall under a load of 24 000 liters of water during an overhead lifting or lowering/braking operation. The flexing is magnified for illustration purposes but is an accurte reflection of what happens in practice. This places the side wall under severe bending stress and can result in plastic bending of the side wall section.

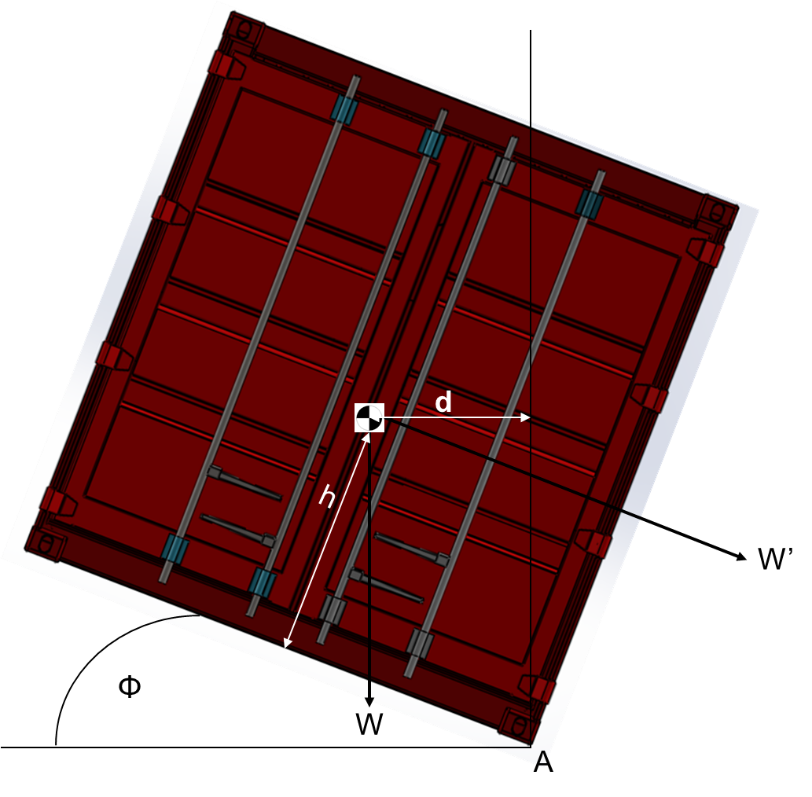

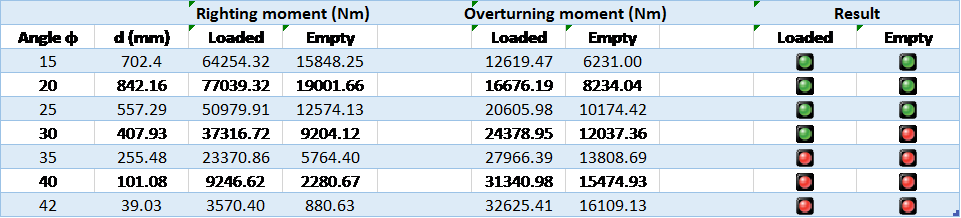

Static storage facility utilizing standard ISO shipping containers and located at ............ may be subject to seismic activity. The containers are standard type ISO type 22G1 shipping containers of 20 ft length. Average container tare weight is 2 300 kg and gross mass is 30 480 kg. In the event of severe seismic events vertical forces acting on the base of the containers may generate large overturning moments. This analysis investigates the overturning and righting moments about the longitudinal axis of the container so as to determine the potential for the containers to overturn during a seismic event. Primary references material is the NEHRP Recommended Seismic Provisions for New Buildings and Other Structures. 2009 Edition. Only vertical forces are considered. Base shear forces and fundamental frequencies of containers are ignored as the containers are not structurally anchored to the ground.